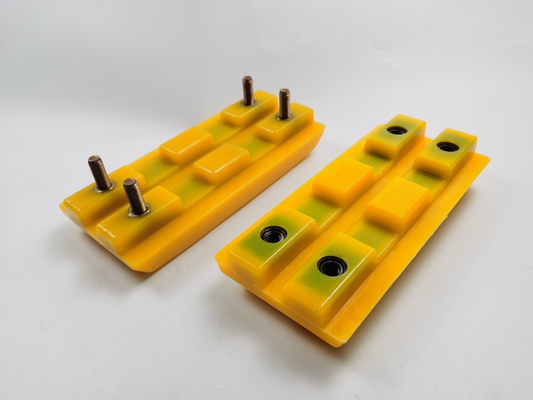

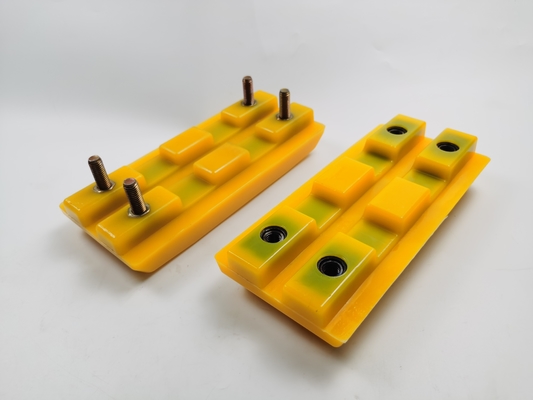

When it comes to milling machine spare parts for W1900, W2000, and W2100 models, the 2411112 Polyurethane EPS pad stands out as a crucial component. Specifically designed for these milling machines, this pad serves as a vital element in the milling process, providing effective cushioning, stability, and precision.

The W1900, W2000, and W2100 milling machines are widely used in road construction and maintenance projects for removing old asphalt surfaces and preparing them for resurfacing. To ensure optimal performance and longevity, it is essential to have high-quality spare parts, such as the 2411112 Polyurethane EPS pad, which is specifically designed to meet the requirements of these machines.

The 2411112 Polyurethane EPS pad is made from polyurethane material, which offers excellent durability, flexibility, and resistance to wear. This resilient material allows the pad to withstand the harsh milling conditions, including contact with the road surface, debris, and variations in temperature.

One of the key functions of the Polyurethane EPS pad is to provide cushioning between the milling machine and the road surface. As the milling drum rotates and removes the asphalt, the pad acts as a protective layer, minimizing the impact on the machine and ensuring a smooth and controlled milling operation. It helps reduce vibrations and shocks, preventing damage to both the machine and the surface being milled.

The EPS (Expanded Polystyrene) properties of the pad contribute to its lightweight nature, making it easy to handle and install on the milling machine. Despite its lightness, the pad maintains its structural integrity and stability, ensuring consistent performance throughout the milling process. This feature also helps reduce the overall weight of the milling machine, improving maneuverability and efficiency on the job site.

Installing the 2411112 Polyurethane EPS pad on the W1900, W2000, or W2100 milling machine is a straightforward process. The pad is designed to fit securely onto the machine's drum housing, providing a stable and reliable connection. Once installed, it effectively absorbs shocks and impacts, allowing for precise milling operations and maintaining the integrity of the machine's components.

The Polyurethane EPS pad plays a critical role in achieving accurate milling results. Its cushioning properties reduce the risk of surface irregularities, ensuring a smooth and even milled surface. This is particularly important for road resurfacing projects, as it provides a solid foundation for the new asphalt layer and contributes to the longevity of the road.

Regular inspection and maintenance of the Polyurethane EPS pad are necessary to ensure optimal performance. This includes checking for signs of wear, damage, or deterioration and replacing the pad when necessary. Proper care and maintenance of the pad contribute to consistent milling results and extend its lifespan.

In summary, the 2411112 Polyurethane EPS pad is a vital spare part for W1900, W2000, and W2100 milling machines. Its polyurethane material, cushioning properties, and lightweight design make it an essential component in the milling process. By incorporating this pad into the milling machine, contractors can achieve precise and efficient milling operations, ensuring high-quality results in road construction and maintenance projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!