Product Details

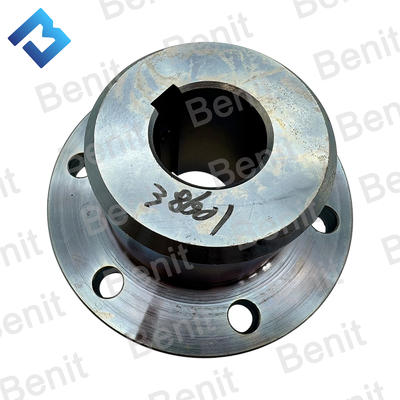

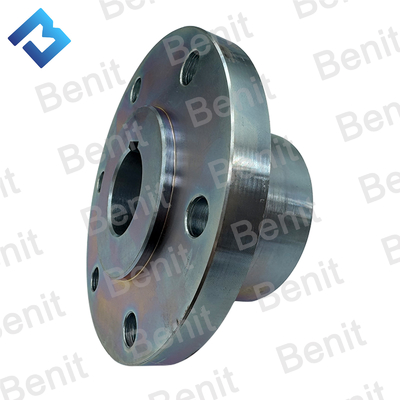

High Quality Drive Flange for W2000 Milling Machine (Part No. 38601) – Precision Power Transmission Component

Critical Power Transfer Interface

The High Quality Drive Flange (Part No. 38601) serves as the vital mechanical interface that connects the W2000 milling machine's hydraulic motor to its drive roller system. This precision-engineered component forms the essential link in the power transmission chain, converting hydraulic energy into controlled mechanical movement for the machine's cutting operations.

Advanced Engineering Specifications

-

Robust Construction

-

High-tensile forged steel construction

-

Precision-machined mounting surfaces

-

Hardened contact points for wear resistance

-

Performance-Optimized Design

Operational Significance

-

Power Transmission

-

Efficient torque transfer from motor to roller

-

Maintains consistent power delivery

-

Minimizes energy loss in drive system

-

System Integrity

-

Absorbs operational vibrations

-

Maintains perfect shaft alignment

-

Protects connected components

Durability Features

-

Longevity Enhancements

-

Wear-resistant gear teeth

-

Stress-relieved material structure

-

Protected bearing surfaces

-

Failure Prevention

Maintenance Requirements

-

Service Protocols

-

Regular bolt torque verification

-

Lubrication of mating surfaces

-

Inspection of spline condition

-

Replacement Indicators

Installation Specifications

Precision-engineered for:

-

W2000 series milling machines

-

Direct drive roller connection

-

Hydraulic motor interface

-

OEM part number 38601 applications

Performance Advantages

-

Operational Efficiency

-

Maintains power transmission efficiency

-

Reduces parasitic energy loss

-

Ensures consistent roller speed

-

Component Protection

-

Prevents shaft misalignment damage

-

Extends hydraulic motor life

-

Protects roller bearing systems

Conclusion: The Heart of Milling Power Transfer

This drive flange represents more than just a simple mechanical coupler - it's the critical nexus where hydraulic power becomes mechanical action in the W2000 milling system. Its precision manufacturing and material selection directly impact the machine's cutting performance, fuel efficiency, and overall reliability.

The component's OEM-quality construction ensures perfect compatibility with Wirtgen's exacting specifications, delivering performance that aftermarket alternatives cannot match. Proper maintenance and timely replacement of this flange helps prevent catastrophic drive system failures and maintains the W2000's renowned productivity in demanding milling conditions.

For optimal performance, technicians should incorporate flange inspection into regular maintenance routines and replace the component at the first signs of wear or deformation. This proactive approach protects the substantial investment in milling equipment and ensures consistent performance throughout the machine's service life.

Product Parameters

| Part Name |

Drive Flange |

| Machine |

milling machine |

| Machine Model |

W2000 |

| MOQ |

1pcs |

| Position |

spare parts |

| Origin |

Yes |

| weight |

4kg/pcs |

| Position |

undercarriage System |

Company Profile

Suzhou Benit Machinery Technology Co.Ltd is specialized in manufacturing and retailing after-market parts of asphalt paver, milling machine and road roller. We provide daily maintenance, overhaul and technical service for our customers. Our main products includes: 1. For asphalt paver,tamper heating tube,paver ultrasonic sensor,abg525 2197266 sensor sonic de nivelamento,high quality asphalt paver cable string electronic wire for leveling sensor. 2. For milling machine,type2 b145l scraper blade 146461,conveyor support roller,rubber belt. 3. For road roller,shock absorber rubber buffer, water pump and spray nozzle and other various road construction euipment parts.

Benit is loed in Home of German Enterprises - Taicang. With its splendid geographical position, Benit enjoys convenient water, land and air transportation, which ensures its timely delivery and export. Benit has distributed its products all over the world, such as Luxembourg, Nigeria, Portugal, Sudan, Tunisia and established a stable and friendly cooperation relationship with those companies.

Benit will always adhere to its management concept,”honest, quality first,service first”, constantly upgrading its products and making more innovations. We offer professional technical support, perfect after-sales service and complete product stock to every road construction company, aiming to live up to all their expectations.

Benit is going to be stronger with the support of all our dear clients. We warmly welcome you to contact us for future business relationship and are sincerely looking forward to working with you.

FAQ

Q1.Are you a manufacture?

A1:Yes,we have workshops and automatic production lines of cutting teeth. As for other parts, we are OEM supplier.

Q2.What is your supply ?

A2.Annual output numorous parts

Q3.Can you provide samples?

A3.We can provide samples, but clients have to pay the sample fee and freight.

Q4.Do you have a minimum order?

A4. Yes, It is up to different products. Usually MOQ 1pcs is acceptable.

Q5. What is your delivery time ?

A5. Around 7-10 days depend which products and quantities, please confirm with sales rep.

Q6.Payment terms?

A6. TT, LC at sight , DP are all acceptable / negotiable and case to case.

Q7. CIF / FOB / EXW etc..

A7. FOB Shanghai or EXW with factory address at Taicang, Suzhou city, Jiangsu province. Pls send destination port for quote on CIF.

Q8. Shipping

A8: Air freight cargo,Train or sea shipment.

Product photos

Warehouse&Production Line

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!