Precision at a Glance: The Benit LCD Display for Advanced Milling Machine Control

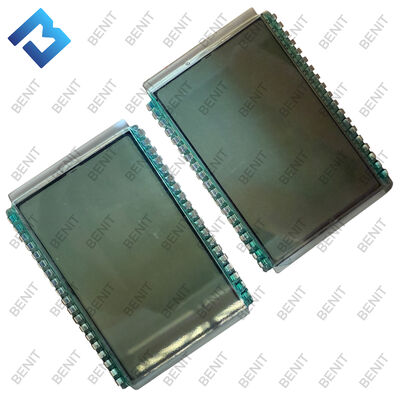

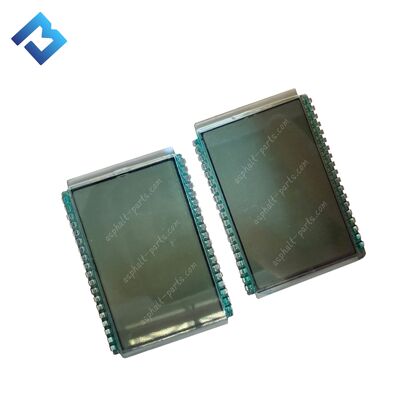

In the high-stakes environment of modern road rehabilitation and precision milling, the operator's command center is paramount. The interface through which complex machine functions are monitored and controlled directly influences productivity, accuracy, and safety. For sophisticated cold planers like the Wirtgen W2000, renowned for their power and precision, a clear, reliable, and intuitive control system is the nerve center of the entire operation. The Benit High-Quality LCD Display, engineered as a direct replacement dual-screen controller unit, fulfills this critical role. Designed to seamlessly integrate with the W2000 milling machine, this advanced display system, compatible with key industry part numbers such as 115640, 161400, and 2075279, restores and enhances the vital link between the operator and the machine's intricate electronics, ensuring command is always precise and informed.

The core function of the Benit LCD Display is to present a comprehensive, real-time visual stream of the machine's operational status. Replacing the original dual-screen setup, it serves as the primary dashboard for all essential parameters. This includes critical data on engine performance, hydraulic system status, milling drum rotation and speed, machine travel velocity, and the precise control of the milling depth and slope. Modern road milling demands extraordinary accuracy to achieve specified grades and surface textures, and this clarity of information is non-negotiable. The high-quality LCD technology ensures bright, sharp, and high-contrast visuals that remain readable in all lighting conditions—from the glare of direct sunlight to low-light evening operations. This eliminates guesswork and allows the operator to make instantaneous, data-driven adjustments, ensuring the milling process adheres exactly to the engineering plan.

Beyond mere monitoring, this display unit is the central hub for machine configuration and control. It facilitates access to and programming of the machine's automated functions, which are essential for consistent, high-quality results. Operators can input and monitor milling depth profiles, control side-shift extensions, and manage conveyor swing functions, all through an intuitive interface. The reliability of this unit is its most crucial asset. Constructed with industrial-grade components, it is built to withstand the relentless vibrations, temperature extremes, and dust inherent to construction sites. A failure in this component can bring an entire multi-million-dollar machine to a standstill, causing massive project delays. The Benit display acts as a robust and dependable nerve center, engineered to deliver stable performance shift after shift, preventing costly electronic downtime and maintaining continuous workflow.

Ultimately, the Benit LCD Display is far more than a simple screen; it is a vital component for operational excellence and asset management. By providing operators with flawless visual feedback and control, it empowers them to utilize the W2000's full capabilities safely and efficiently. This leads to optimal milling performance, superior surface finish quality, and maximized machine productivity. For fleet managers and equipment owners, installing this high-quality replacement unit is a strategic investment in maintaining the integrity and value of a critical piece of road construction equipment. It ensures that the sophisticated electronics of the W2000 milling machine continue to function as intended, safeguarding both the machine's output and its long-term operational viability on demanding job sites around the world.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!